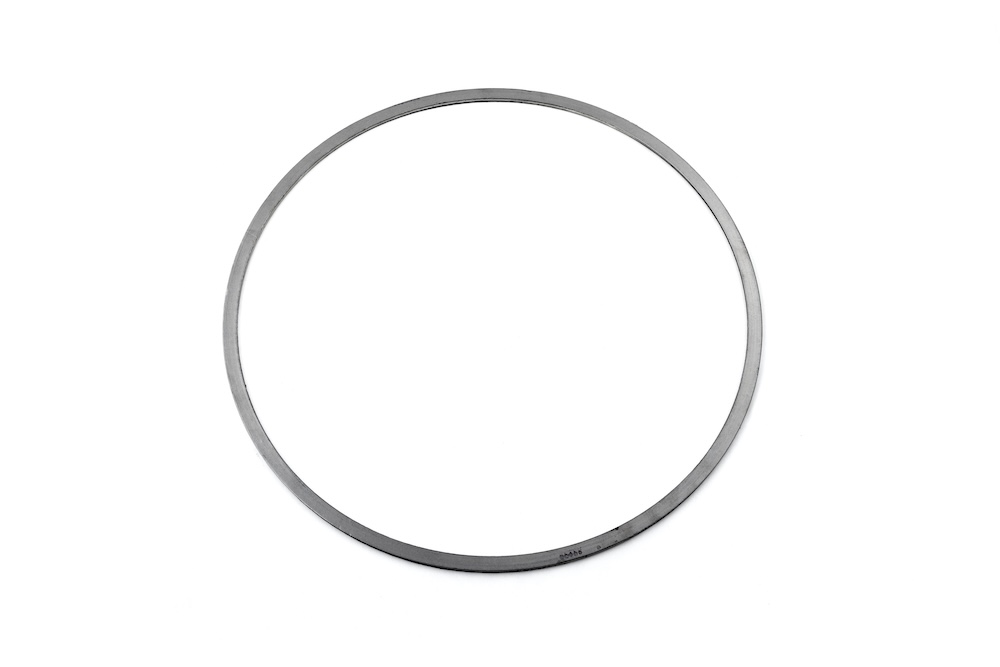

KAG® Gasket

Description

The KAG® is a Kamprofile gasket with APX2 graphite facings, originally developed by Chevron for use in heat exchangers and other fixed equipment. Backed by extensive field and laboratory research, every design parameter of the KAG® has been precisely engineered to deliver optimal performance and reliability in the demanding conditions of heat exchangers.

Application

The KAG® gasket is for use in heat exchanger girth flanges, especially where the width of the gasket is less than ½”. When properly installed in code-designed flanges, the KAG® gasket is suitable for service pressures to 3,000 psi. It has been successfully used in tens of thousands of heat exchangers worldwide, resulting in leak-free sealing from turnaround to turnaround.

Sealing Characteristics

- Provides turnaround-to-turnaround reliability. When properly installed, the KAG® gasket resists damage from radial shear forces, allowing it to remain tight through the entire service cycle.

- Replaces multiple styles of gaskets.

- Constructed of fire-safe materials.

- APX2 flexible graphite facings have extremely low oxidation rates at elevated temperatures, making the KAG® gasket suitable for services up to 1,000°F.

- Can be used in flanges with nubbins.

Chemical Compatibility

Materials of construction can be selected to meet the chemical demands of any service. Engineering and design guidance are available on request.

Available Options

Core materials are available in 304 or 316 stainless steel as standard, with additional alloys offered upon request. Custom configurations are available, including double-rail and full-face designs.

Approvals & Certificates

APX2 is a fire-rated material, along with any gasket incorporating it as a component. For additional information, please consult the Engineering team.

DOWNLOAD