High-Density Low-Emission Gasket

Description

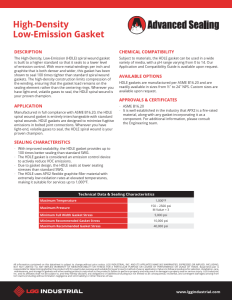

The High-Density, Low-Emission (HDLE) spiral wound gasket is built to a higher standard so that it seals to a lower level of emission control. With more metal windings per inch and graphite that is both denser and wider, this gasket has been shown to seal 100 times tighter than standard spiral wound gaskets. The high-density construction limits compression of the winding, ensuring that the gasket load remains on the sealing element rather than the centering rings. Wherever you have light-end, volatile gases to seal, the HDLE spiral wound is your proven champion.

Application

Manufactured in full compliance with ASME B16.20, the HDLE spiral wound gasket is entirely interchangeable with standard spiral wounds. HDLE gaskets are designed to minimize fugitive emissions in bolted joint connections. Wherever you have light-end, volatile gases to seal, the HDLE spiral wound is your proven champion.

Sealing Characteristics

- With improved sealability, the HDLE gasket provides up to 100 times better sealing than standard SWG.

- The HDLE gasket is considered an emission control device to actively reduce VOC emissions.

- Due to gasket design, the HDLE seals at lower seating stresses than standard SWG.

- The HDLE uses APX2 flexible graphite filler material with extremely low oxidation rates at elevated temperatures, making it suitable for services up to 1,000°F.

Chemical Compatibility

Subject to materials, the HDLE gasket can be used in a wide variety of media, with a pH range varying from 0 to 14. Our Application and Compatibility Guide is available upon request.

Available Options

HDLE gaskets are manufactured per ASME B16.20 and are readily available in sizes from ½” to 24″ NPS. Custom sizes are available upon request.

Approvals & Certificates

- ASME B16.20

- It is well established in the industry that APX2 is a fire-rated material, along with any gasket incorporating it as a component. For additional information, please consult the Engineering team.

DOWNLOAD